The final quarter rush is here, where delivery capability is proven by production lines running at maximum capacity, an unwavering commitment to millimeter-perfect quality, and seamless organizational synergy. Team Kortrong is in full sprint mode: operating at 100% capacity with a mission to deliver.

01 Uncompromising Precision, Agile Delivery

Speed is secondary to precision.

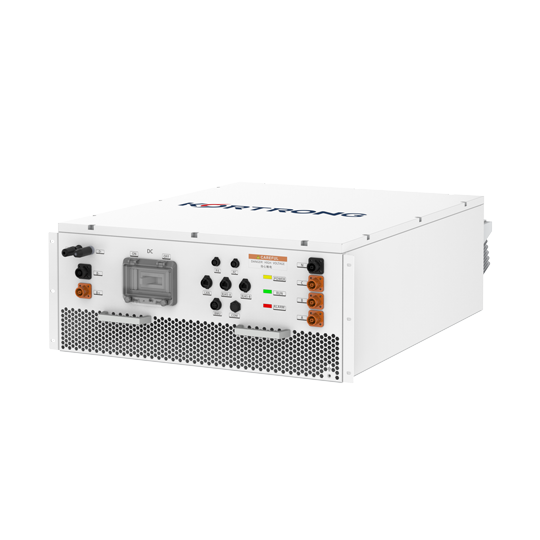

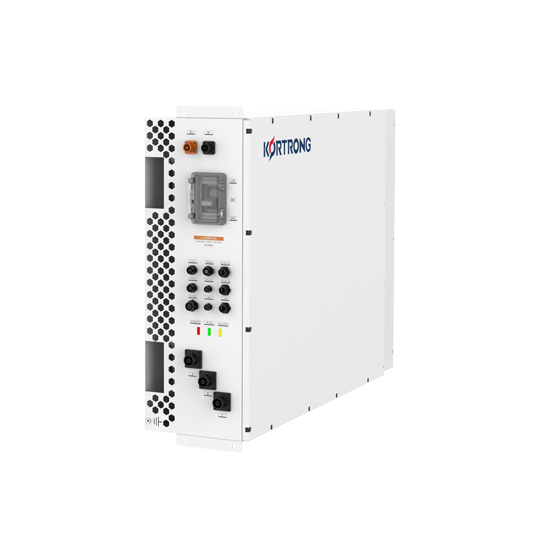

Our automated PACK line is equipped with an intelligent vision positioning system achieving an accuracy of ±0.2mm, ensuring perfectly aligned module stacking. Terminal height measurement precision reaches ±0.05mm, guaranteeing uniform cell connections and minimal contact resistance from the source.

Paired with a 99.5% success rate in automated Open Circuit Voltage (OCV) scanning, we achieve full-process traceability for every individual cell. With torque controlled to within ≤0.1N·m, we ensure consistent and reliable performance at every connection point.

Built on this foundation, a cell gripping speed of 10 cells per minute supports the high-efficiency output of up to 130 battery packs daily, offering the flexibility to accommodate various mainstream cell specifications. The flexible and agile automated production line in our PACK workshop is engineered to meet diverse global order demands.

02 Enhancing Quality & Efficiency: A Proactive Defense

Under full-capacity production, the quality front line must advance proactively, with the focus shifting decisively to prevention and process control.

To address the common industry challenge of poor soldering in PACKs, we have implemented systematic process iteration through fixture optimization, process parameter calibration, dedicated roles, and a strict first-article inspection system.

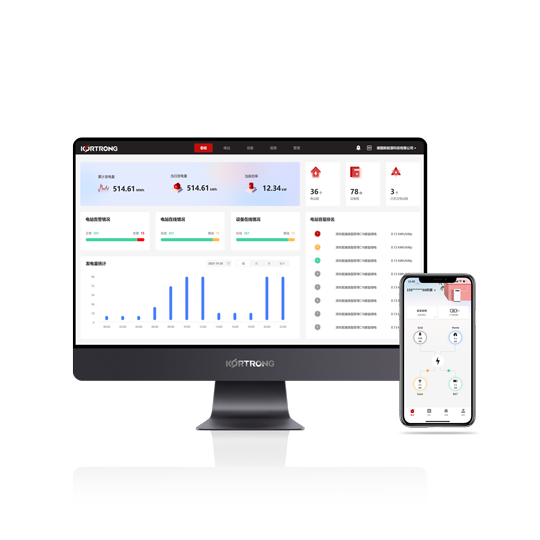

Deeper control is rooted in data and systems: we employ Statistical Process Control (SPC) for real-time monitoring and early warning of key production metrics. Integrated with our Manufacturing Execution System (MES), this enables full-process digital traceability, allowing any anomaly to be pinpointed within seconds and addressed in a rapid, closed-loop manner.

03 Engineering Culture: The Foundation of Delivery Resilience

Delivery resilience is ultimately forged by a self-driven initiative to conquer bottlenecks head-on.

Previously, to tackle a critical assembly efficiency bottleneck, teams from the PACK and final assembly workshops spontaneously organized skills competitions. By jointly deconstructing work procedures, optimizing tool paths, and refining techniques, they achieved a 40% efficiency gain. This effort not only secured the on-schedule grid connection for the Xinjiang project but also propelled the monthly output value at our Zhuhai headquarters to a new peak of 400MWh.

This inherent drive is embedded in Kortrong's engineering DNA: the proactive translation of frontline experience into replicable solutions, continuously iterating to build genuine and enduring delivery resilience.

Navigating the complex interplay of scale, efficiency, and demand, Kortrong's commitment remains unequivocal: to ensure the stable reliability of every single unit and safeguard asset security throughout its entire lifecycle.