Sales of new energy heavy trucks reached 137,800 units in the first three quarters of this year, with a penetration rate exceeding 24%, signaling that the market has crossed the inflection point for scale-up. In some mining areas in Inner Mongolia and Henan, fuel vehicles have been explicitly banned from entry, allowing only green-powered heavy trucks—green transformation is shifting from macro planning to micro reality.

01 Supercharging vs. Battery Swapping: Cost Trade-offs of Different Models

In the choice of technology routes for new energy replenishment, battery swapping and supercharging represent two distinct business logics.

Battery swapping mode is essentially "efficiency-first heavy asset operation," with its core costs lying in building a complete battery circulation ecosystem: including massive asset investments in spare battery packs, full-cycle maintenance costs to sustain battery performance (constant temperature storage, testing and maintenance, logistics scheduling), which is a path that trades heavy asset inputs for ultimate replenishment efficiency.

In contrast, supercharging mode only provides energy, without involving battery asset management (batteries remain on the vehicle), thereby completely avoiding the burden of full life-cycle management for spare batteries. With the maturity of megawatt-level supercharging technology, replenishment efficiency has achieved major breakthroughs.

At the current critical stage where heavy truck electrification is moving toward scale, the industry faces challenges that have deepened from single replenishment efficiency to systemic tests of grid carrying capacity, investment economics, and operational reliability.

02 Three-in-One: Safety, Cost Reduction, Grid-Friendly

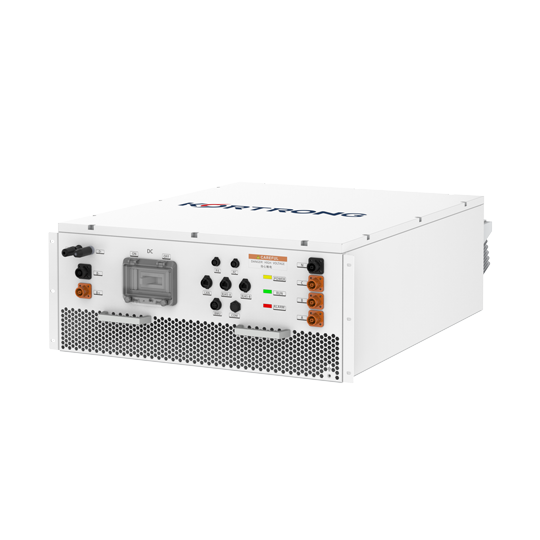

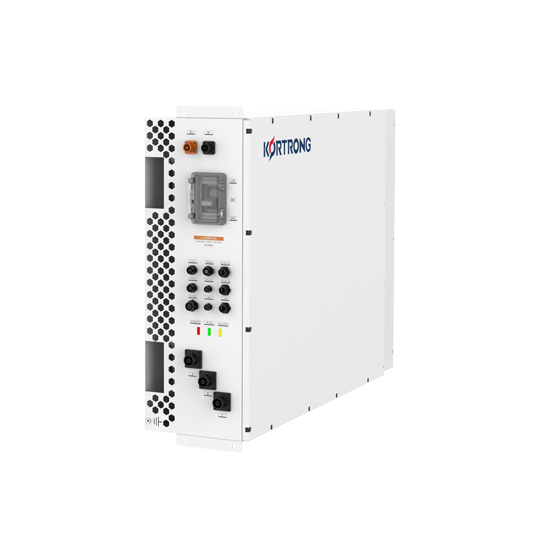

Kortrong's multi-energy complementary super energy storage charging station solution, with grid-forming energy storage as the core hub, can effectively smooth renewable energy output fluctuations, support instantaneous supercharging high-load demands, and build a stable operation foundation for MW-level supercharging networks.

To address the heat dissipation and safety bottlenecks of heavy truck supercharging, this solution adopts mature immersion liquid cooling technology, achieving fast, uniform full-process constant temperature control, while solving the temperature control problem of charging guns, completely eliminating thermal runaway risks, and extending battery life by more than 30%, directly ensuring investment returns and operational reliability of supercharging facilities.

Additionally, the solution uses high-voltage direct-hanging electronic transformer technology to replace traditional power frequency transformer +0.4kV rectification charging systems, realizing direct conversion from 10kV AC to DC, with comprehensive conversion efficiency above 98.5%, an improvement of 3-5% over traditional systems, directly reducing power losses and enhancing charging business profit margins. At the same time, the simplification of the system architecture significantly lowers initial equipment investments and grid transformation costs.

Through systemic technology optimization, Kortrong's multi-energy complementary super charging station solution avoids massive grid transformation investments while directly reducing costs from both initial investments and long-term operations and maintenance.

03 Reliable Solutions Adapted to All Scenarios

Our full-chain technology and management capabilities verified in large-scale energy storage projects have been replicated in the construction of heavy truck charging scenarios. Targeting the complex operating conditions of heavy trucks, we have forged high adaptability and high reliability system assurance capabilities.

Through modular design and system strengthening, the system possesses high protection and wide temperature range working capabilities, unafraid of weak grids and harsh climates, ensuring stable operation in complex scenarios such as ports, mining areas, and trunk logistics.

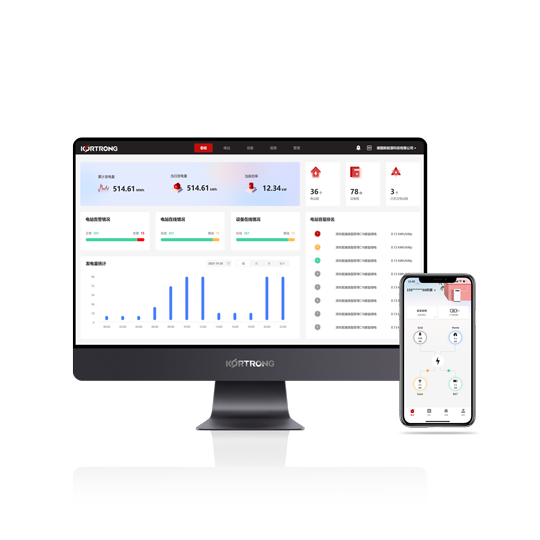

Relying on an intelligent operations and maintenance platform, we have built a full life-cycle asset protection system from "passive repair" to "active warning," with real-time diagnosis of equipment health and precise intervention in potential risks.

Let every investment anchor in predictable long-term value, with excellent operational reliability, to win the future of heavy truck electrification together with investors, and jointly step into a new era of green transportation.