As demand for grid-scale storage solutions surges worldwide, manufacturers face unprecedented pressure to deliver high-quality systems at unprecedented speed. Kortrong's vertically integrated manufacturing strategy has transformed this challenge into a decisive competitive advantage – converting precision engineering into measurable market leadership.

01. IGNITE INTELLIGENT MANUFACTURING: Doubling Capacity, Securing Delivery Leadership

Powered by a fully self-developed 12GWh digital factory, Kortrong redefines production benchmarks with 90%+ core-line automation. This technological foundation has driven transformative results: daily PACK output surged 30%, while final assembly and commissioning efficiency doubled—critical breakthroughs enabling the company to accelerate toward 400-500MWh monthly delivery capacity. By aligning smart factory infrastructure with dynamic demand, Kortrong ensures not just scale, but predictable scale—a cornerstone of trust for global partners navigating the energy transition.

02. EFFICIENT DELIVERY ENGINE: Synergy, Safety, and Uninterrupted Velocity

At the heart of Kortrong’s operational excellence lies a dual commitment to lean synergy and uncompromising safety. Through adaptive cellular manufacturing and real-time workflow optimization, the production ecosystem maximizes asset utilization and throughput, turning complex supply chains into a synchronized value stream. Complementing this agility is an institutionalized risk control framework, where robust safety mechanisms and end-to-end risk management protocols ensure operational continuity. This balance—efficiency without sacrifice—positions Kortrong to meet aggressive delivery timelines even amid industry-wide volatility.

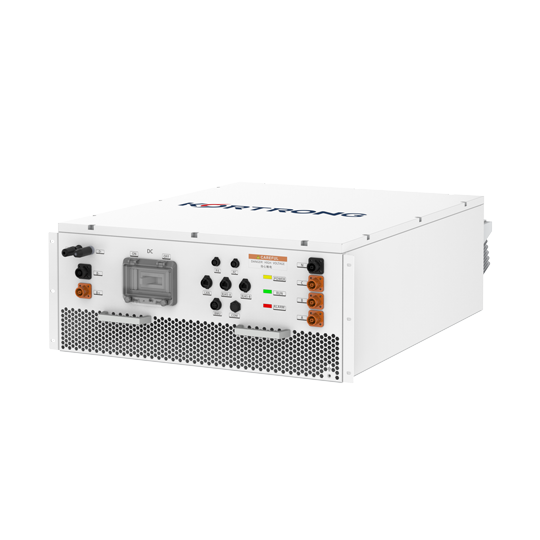

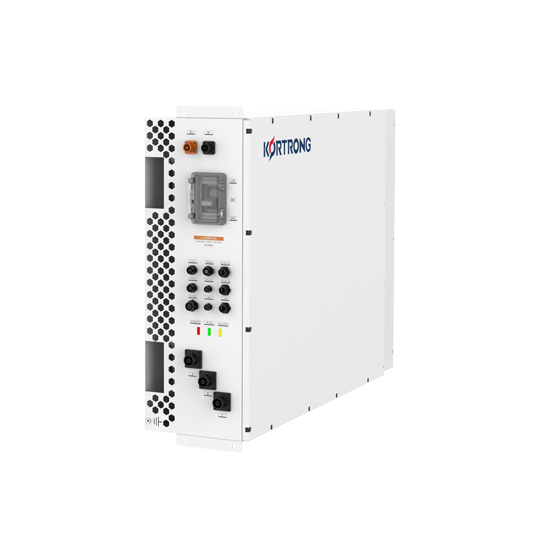

03. END-TO-END QUALITY SOVEREIGNTY: Precision, Proactivity, and Closed-Loop Control

Quality is not an endpoint at Kortrong; it is embedded in every stage of production. With 40 critical quality checkpoints and 21 precision validation stages, the manufacturing process operates as a closed-loop system, where digital QC tools drive near-zero defects while boosting resource efficiency. What truly distinguishes Kortrong, however, is its full-chain in-house R&D mastery. By owning every stages from cell chemistry to system integration, the company enables proactive quality intervention—identifying potential issues before they arise and engineering solutions that elevate performance standards industry-wide.

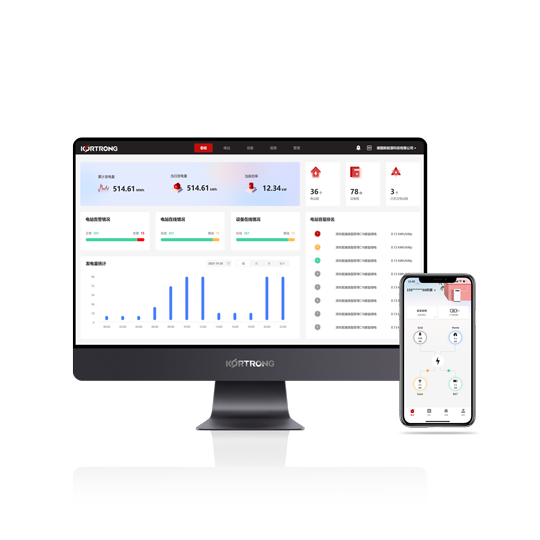

04. DIGITAL PERFORMANCE AMPLIFIER: Intelligence That Transforms Operations

The backbone of Kortrong’s manufacturing prowess is its unified system intelligence. Seamless integration of MES, WMS, and ERP platforms automates the entire PACK lifecycle—from production and inspection to warehousing and dispatch—eliminating bottlenecks and human error. Layered atop this infrastructure is predictive operational insight: real-time data translation empowers executives to intercept anomalies proactively, turning raw metrics into decisive action. In an industry where milliseconds matter, this digital edge ensures Kortrong stays ahead of disruptions and delivers with unmatched precision.

The Reliability Benchmark

Kortrong's manufacturing excellence transcends speed metrics. We deliver Tier-1 reliability at scale through an integrated model blending precision engineering with digital connectivity. As the industry grapples with supply chain volatility, this fusion positions global partners for the storage-first energy transition. When your projects require not just batteries, but guaranteed performance certainty, the manufacturing choice becomes unequivocal.