According to CESA Energy Storage Application Branch industry data, the Middle East market recorded a staggering 33.95 GWh in overseas partnerships/orders from January to May 2025. The region has emerged as a key global growth market for energy storage, firmly entering the era of GWh-scale projects. While industry leaders fiercely compete for mega-projects, a new chapter is unfolding in specialized application scenarios: the rise of hybrid off-grid power systems.

01. Powering the Nod: The Hidden Cost of Weak Grids & Power Surges

Across the Middle East, vast desert landscapes are dotted with arrays of "nodding donkeys" (oil pumpjacks) methodically extracting crude. These oilfields, often located in remote areas far from main power grids, face significant challenges due to weak grid infrastructure, complicating power transmission and distribution.

Oilfields typically rely on two primary power sources: captive power plants or standalone diesel generators. Large-scale operations usually necessitate captive power plants. However, plant construction is lengthy – even small plants take nearly two years, delaying field development. Building the required localized grid also incurs high transmission line costs. Fuel storage, transportation, and ongoing maintenance add substantial operational complexity and burden.

Opting for standalone diesel generators brings its own challenges: high capital expenditure (CAPEX) and exorbitant operating costs (OPEX). To handle intermittent, high-power load surges, generators must be significantly oversized ("over-provisioned"), leading to wasted initial investment. Continuously high diesel costs make electricity extremely expensive. Furthermore, 24/7 operation drastically shortens generator lifespan to just 2-3 years due to accelerated wear. In comparable Chinese scenarios, the average Levelized Cost of Electricity (LCOE) can reach ~¥3/kWh, resulting in cripplingly high OPEX.

02. Slash Costs by 30%: Why Hybrid Microgrids Are the New Power Play

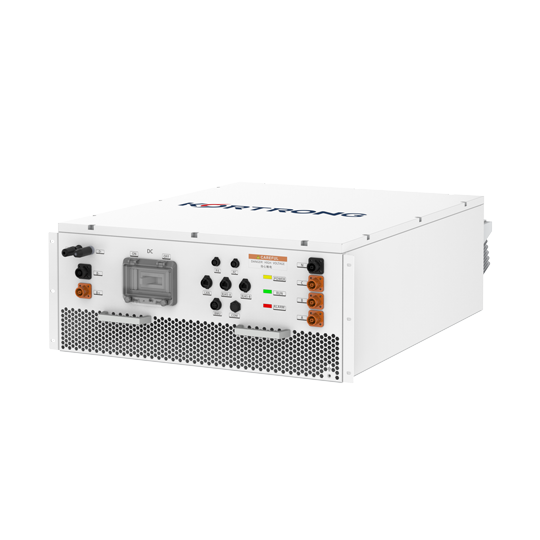

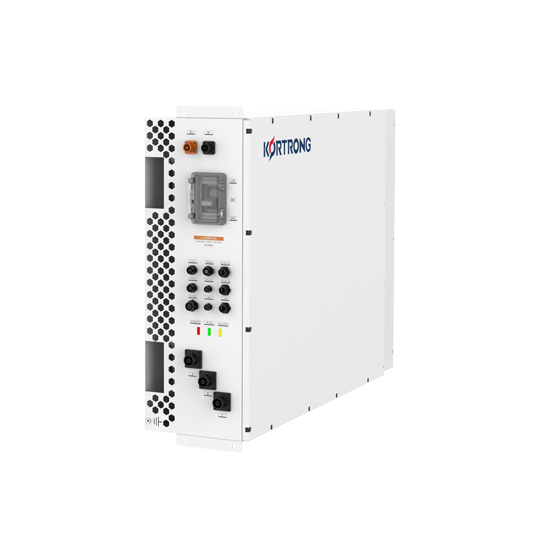

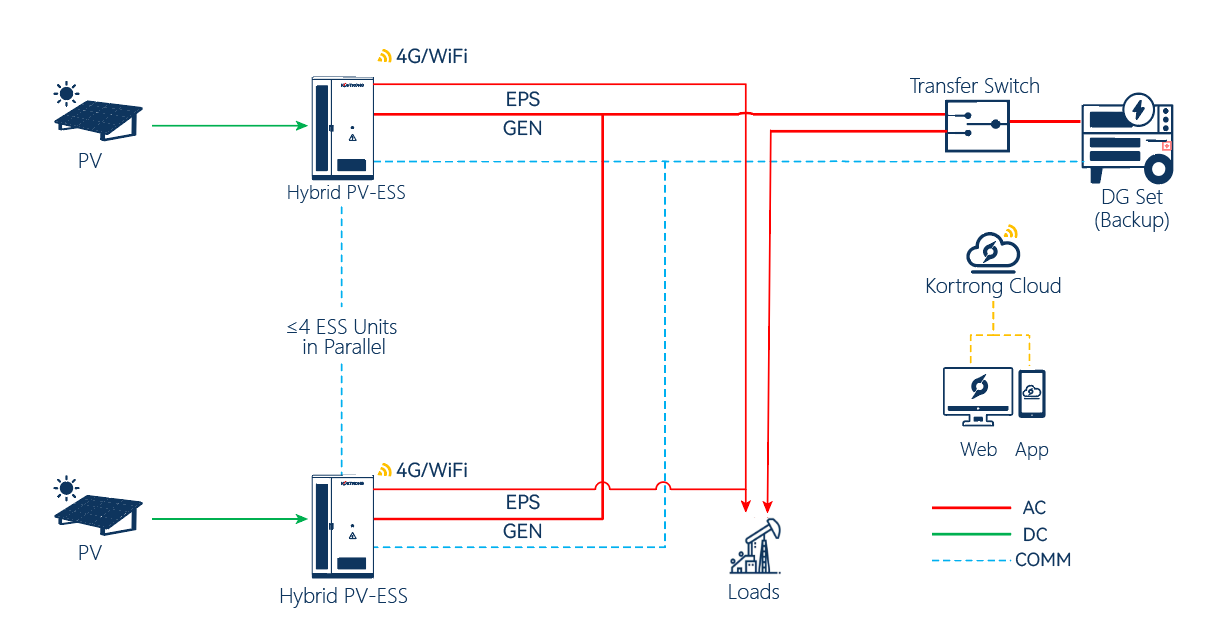

Kortrong addresses these core power challenges with a custom hybrid microgrid solution tailored for large Middle Eastern oilfields. This solution will be formally introduced to partners at the upcoming Saudi Solar & Energy Storage Show in October.

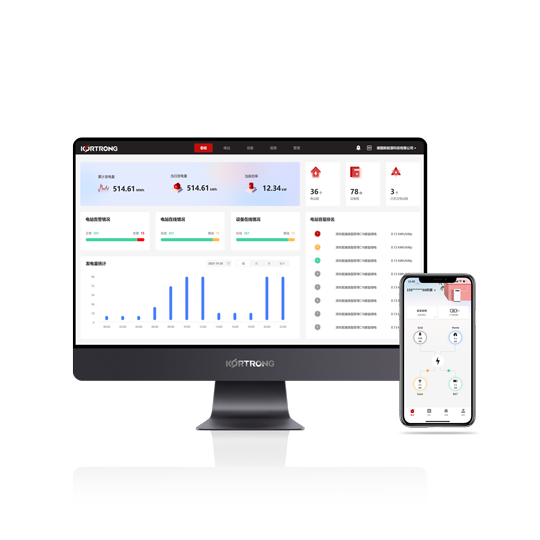

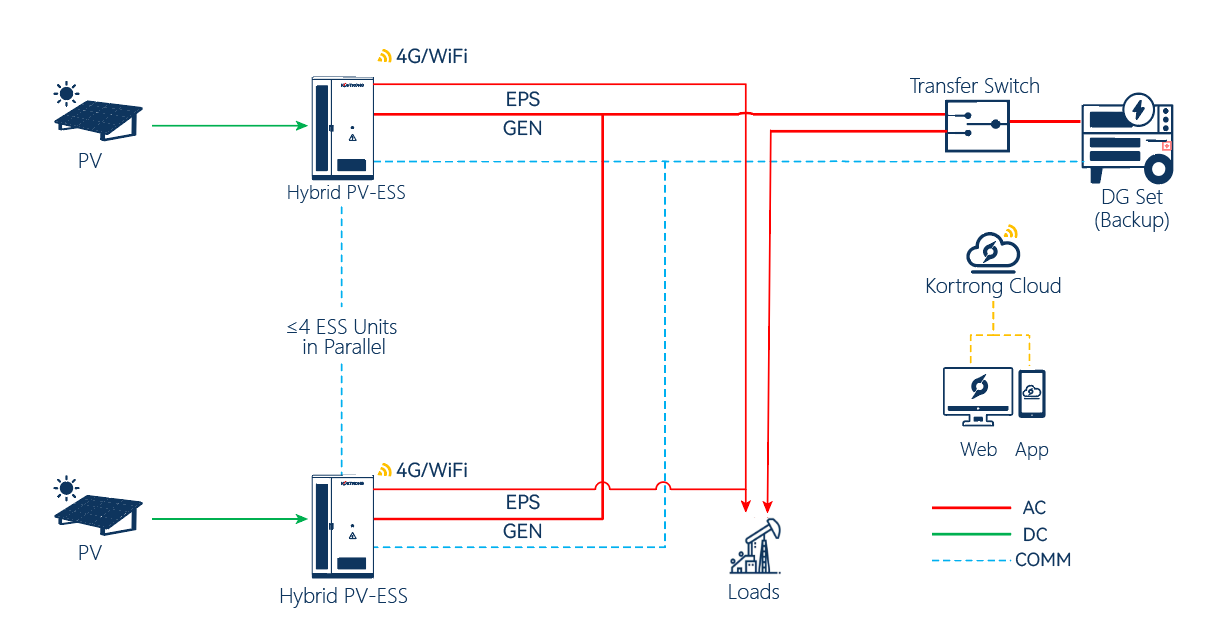

This microgrid utilizes solar PV and energy storage as the primary power source, displacing diesel generators, localized grids, and grid power – relegating diesel gensets to backup duty. An AI-powered smart energy management system enables load forecasting and optimized dispatch, effectively solving power supply issues in weak-grid areas. Demonstrated advantages in comparable Chinese deployments include:

> 30% Reduction in Electricity Costs: Green power replaces diesel generation. The storage system smooths loads by absorbing and releasing power during peak demand, reducing grid stress and enhancing stability. Businesses benefit from lower-cost renewable energy settlements, slashing OPEX by over 30% compared to traditional diesel power.

Lower CAPEX & OPEX: Eliminates the need for oversized diesel generators. High-power load surges are managed ("absorbed") by the solar-storage system, reducing investment in backup/high-capacity gensets. The reduced runtime extends the lifespan of the backup diesel generators, further lowering CAPEX and maintenance costs.

Guaranteed Power Continuity: The system employs grid-forming + fast switching technology, enabling seamless transitions between the hybrid solar-storage-diesel system and the diesel backup during grid failures or genset shutdowns. This provides emergency power, minimizes downtime losses, and ensures uninterrupted oilfield operations.

03. Defying the Desert: An All-Weather Energy Solution

The Middle East's extreme conditions – intense heat and pervasive sand/dust – demand exceptional durability and protection. Prolonged high temperatures degrade battery capacity and lifespan. Frequent sandstorms create major maintenance hurdles, requiring regular cleaning to prevent filter or condenser blockages. Fire risk and equipment safety are paramount concerns, especially near oil & gas facilities or populated areas.

Kortrong's integrated solar-storage system features complete battery cell immersion in coolant, isolating them from air. This eliminates fire hazards at the source by removing two key elements for combustion: temperature and oxygen. Direct liquid cooling enables precision thermal management, maintaining battery cluster temperature differentials within ≤2°C even in extreme heat, aligning system lifespan with that of individual cells. The fully sealed design creates a physical dust barrier, while the coolant medium prevents electrode-dust contact, drastically reducing maintenance needs in high-dust environments.

Amidst the energy transition driven by initiatives like Saudi Vision 2030, the Middle East presents a high-potential market. Leveraging proven success in large-scale projects within China's demanding environments (e.g., Henan, Xinjiang – featuring high heat and sand), Kortrong is poised to deliver cost-effective energy solutions tailored to local needs, supporting the region's energy transformation.