On May 30th, China will celebrate its ninth National Science and Technology Workers' Day, with the theme 'Dedicated to Innovation and Development, Building a World-Class Science and Technology Powerhouse." The innovative advancement of energy storage industries is intrinsically linked to the independent R&D capabilities of end-to-end core technologies. Following the pioneering application of Kortrong's immersion liquid cooling technology in the world's first immersion-cooled energy storage power station, Kortrong Energy Storage has positioned itself as the sole industry player offering mass-produced solutions. With over 2GWh of deployed projects demonstrating the technology's safety, reliability, and operational stability, systems in projects such as Foshan and Xinyang have achieved energy conversion efficiencies exceeding 90%. This article delves into how Kortrong's R&D team achieved this breakthrough.

Pioneering the Path to Safety: A Non-Negotiable Imperative in Energy Storage Innovation

While the industry debated the feasibility of large-scale industrialization of liquid cooling technologies, Kortrong's R&D team had already plunged into the uncharted territories of immersion liquid cooling development, pioneering breakthroughs from concept to commercialization.

Kortrong's team firmly asserts that 'intrinsic safety' is not an optional consideration but a non-negotiable imperative in the energy storage revolution. Safety is the cornerstone upon which the future of clean energy rests.

However, the technical implementation of immersion liquid cooling demands exceptional expertise in thermal management, systemic sealing integrity, and material compatibility, presenting multifaceted challenges that require integrated innovation across disciplines.

Innovative Immersion Liquid Cooling Technology: A Journey of Rigorous Validation and Pioneering Breakthroughs

According to the technical lead, the development of this cutting-edge energy storage solution involved extensive, systematic research and validation. Critical measures included:

1. Material Compatibility Testing: Comprehensive compatibility assessments were conducted on all materials in contact with coolant to ensure stable, long-term operation across the entire lifecycle of the energy storage system.

2. Failure Mode Analysis: Rigorous testing protocols, including unlimited overcharge and short-circuit simulations, were applied to 314Ah-class battery cells. These tests specifically targeted safety-critical failure modes, guaranteeing no thermal runaway or open flame propagation under any failure scenario.

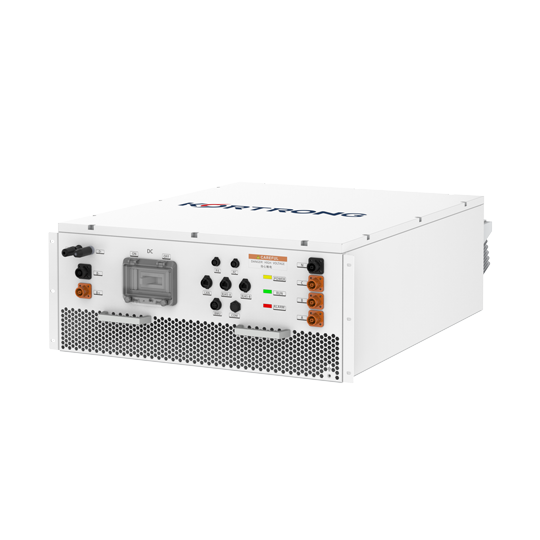

On March 6, 2023, the world's first immersion liquid cooling energy storage station was successfully commissioned at the Meizhou Baohu site. Since then, multiple large-scale immersion cooling projects have maintained stable operation, earning recognition from industry leaders such as China Southern Power Grid. Through this hands-on experience, the team refined its technical approach, advancing the technology from cell cluster-level immersion to module-level immersion—a pivotal evolution in system design.

This breakthrough underscores Kortrong Innovation's core philosophy:

● Root-Cause Problem Solving: Groundbreaking advancements begin with meticulous analysis of fundamental challenges.

●Pioneering Resilience: True innovation thrives in uncharted territories, where relentless validation and precision define success.

Each phase of testing—from material science to failure-mode simulation—laid the foundation for this globally pioneering technology. The journey exemplifies how disciplined rigor and visionary thinking can transform theoretical concepts into scalable, real-world solutions.

Self-Reliance Innovation: A Demand-Driven Differentiated Breakthrough

As industry competition intensifies, technology is redefining market value. Kortrong has consistently adhered to a differentiated path of independent R&D, driven by a client-centric approach. By leveraging holistic technological innovation across the entire ecosystem, Kortrong achieves a differentiated breakthrough, pioneering the industry forward.

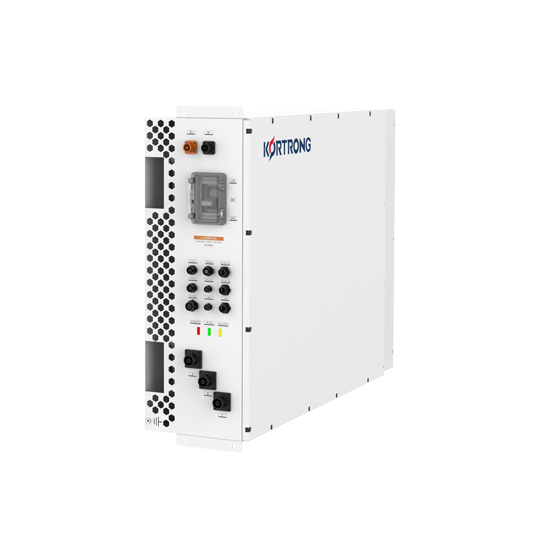

Kortrong's application of PACK-level immersion technology exemplifies a demand-driven, iterative innovation process, spanning from critical component design to holistic performance enhancement. According to the head of Kortrong's R&D Center, the team faced unprecedented challenges during the selection and design of immersion-based PACK systems. With no domestic or international precedents to reference, they navigated uncharted territory through rigorous trial and error.

To balance structural integrity with system performance, the team meticulously conducted repeated structural and thermal simulations. They optimized flow path dimensions through high-precision, high-frequency iterations, ultimately achieving optimal performance outcomes. This approach underscores Kortrong's commitment to innovation that transcends incremental improvements, delivering transformative value to clients.

During the testing phase of the first pack-level immersion prototype, the engineering team recalls enduring relentless exposure to intense sunlight for over two weeks. To simulate real-world high-temperature conditions, engineers subjected the prototype to continuous high-temperature performance and reliability testing under direct solar radiation. Similarly, during the development of an integrated photovoltaic-storage solution, the rooftop photovoltaic-storage matrix of Kortrong's source-grid-load-storage project became a dynamic testbed for the R&D team's technical innovations.

This dual commitment defines Kortrong's R&D ethos: a strategic focus on market-driven technological leadership, paired with meticulous execution of granular, hands-on experimentation. By harmonizing visionary ambition with rigorous empirical validation, the team aims to achieve breakthroughs in both performance optimization and cost-efficiency—cornerstones of sustainable innovation in energy systems.

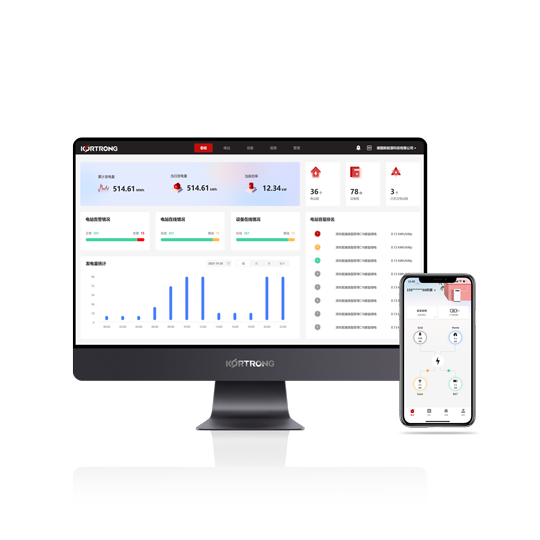

Kortrong Energy Storage: Full-Stack Laboratory with Dual Assurance in Technical Validation

Since 2022, Kortrong Energy Storage has embarked on the ambitious journey of establishing its proprietary Full-Stack Laboratory from scratch. Beginning with a small team of five or six engineers focused on infrastructure development and circuit layout planning during its early stages, the company has now built a comprehensive R&D framework encompassing critical stages such as cell material development, BMS optimization, fire safety systems, thermal management (high/low-temperature testing), chiller performance evaluation, and EMC compliance testing.This robust system is further supported by specialized platforms, including the Material Synthesis Lab, Electrolyte Lab, Chemistry Lab, Physics Lab, and Electrical Performance Lab. Together, these facilities form the backbone of rigorous technical validation, iterative optimization, and continuous innovation, ensuring Kortrong's leadership in energy storage solutions.

"When establishing test environments, our team collaboratively brainstorms optimal solutions through spontaneous discussions," shared a Kortrong Pilot Testing Department engineer. "We replicate various testing environments to rigorously simulate real-world scenarios, conducting iterative defect inspections through multi-cycle debugging."

The validated technical solutions, having undergone stringent verification via laboratory-grade precision instrumentation, deliver enhanced assurance for both operational stability and fail-safe security - effectively implementing dual-layer protection mechanisms.

Kortrong currently maintains an R&D workforce constituting over 30% of its total staff, with more than 300 technology patents secured. Its electrochemistry laboratory has recently earned dual distinctions: the 'Zhuhai Full-Stack Electrochemical Energy Storage Key Laboratory' accreditation and the 'Guangdong Provincial Engineering Technology Research Center' designation.

Kortrong researchers embody the pioneers of the new energy era. Through dedicated endeavors, our innovation team has transformed the vision of clean energy into tangible technological realities, empowering more clients and strategic allies to embrace the conviction: 'Technology transcends abstract concepts - it is the future right bestowed by this transformative age upon every individual.'